5 Y: Root Cause Analysis [Video]

The 5 Y is a quick way to troubleshoot and go deeper with a recurring problem. This technique is helpful for quality improvement and basic problem-solving.

It is most effective when used to resolve simple or moderately complex problems. Add other problem-solving tools like the A3 or PDCA cycle for complex or critical issues.

The 5 Y can be used on an issue that has only one layer of involvement as well as with multiple layers, however, the greater complexity the problem, the more tools will need to be brought in.

The 5Y is an excellent way to teach your team to find the root cause and solve problems.

This simple technique is masterful at getting to the root cause of a problem and is quickly and easily implemented. Consider it your first line of defense when thinking through problems. Use this approach to coach your team before you jump to a solution.

Because of its simplicity, this tool is quite flexible and is often used in the analysis phase of the Six Sigma quality improvement methodology.

Steps to 5 Why’s With Your Team

- Assemble a Team

Your team should be comprised of individuals with firsthand knowledge of the problem. Identify a facilitator who will keep the team focused.

- Define the Problem

Observe the problem in action whenever possible. Have the team discuss and write a brief, clearly stated problem statement that is agreed upon. For example, “The rollout of Project X did not meet the deadline or quality requirements,” and “The admissions team missed its target of daily assessments.”

Using a board or large flipchart paper, write out the statement, leaving room to write in the “why?”

- Ask Why?

Ask your team why the problem is occurring. For example, “Why isn’t the admissions team meeting their daily assessments?”

Asking “Why?” is simple, yet the answer requires thoughtful discussion. You need observable, factual answers. This is not the time to guess or interpret what is happening.

The 5 Y’s is not an exercise in deductive reasoning. You do not want to get sidetracked, creating possible causes that can create confusion as you discuss “what if” scenarios.

This is a simple process to identify the ripple effect of what else may be happening.

Record responses on the board/ paper as your team generates responses using one word or short phrases.

- Ask, “Why?” Four More Times (or as many as needed to get to the root cause)

For each answer you come up with, keep asking, “Why.”

Do not overthink the answers; move quickly from one question to the next, continue to drill down, and get the complete picture.

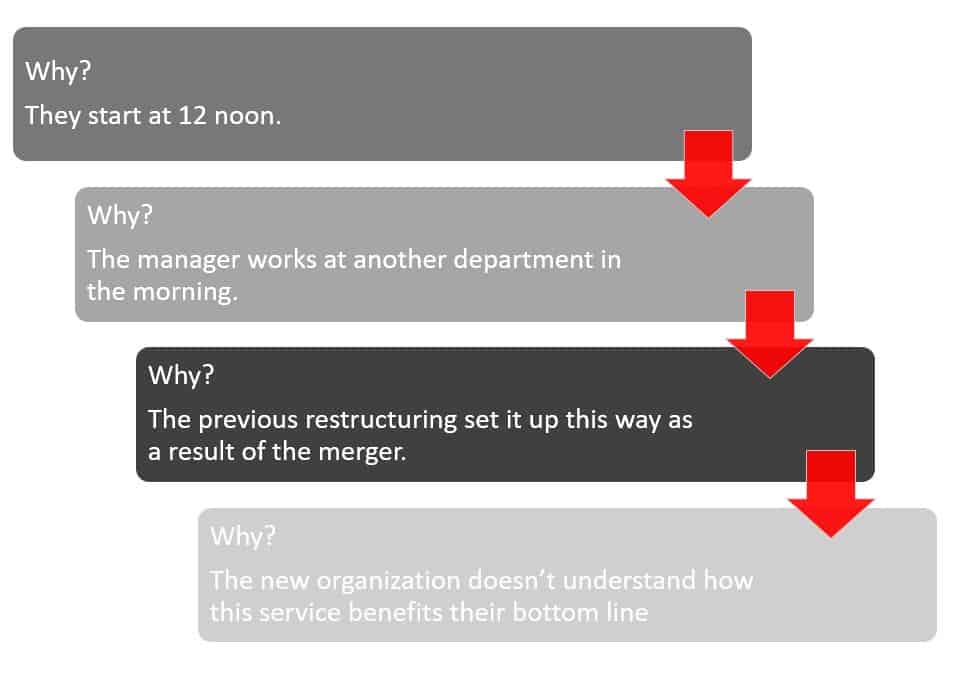

Flowchart Example

Problem Statement: The admissions team missed its target of daily assessments.

You can see from this example that the reasons for the uncovered problems weren’t what you may have thought. Yet, by drilling down, this team discovered some of the unintended consequences of the previous merger and restructuring. Now, they have a direction to find a solution based on facts and observations and not guesses by a management team several levels away from the problem.

Download this worksheet and drill down on your issue. Using this approach as you think about those problems that show up in your day will help you connect the dots to other aspects of what is going on in the environment.

SUPER TIP

The 5Y problem-solving technique may be necessary to get to the root cause. Combine this with other problem-solving tools, and you will be known as the master problem solver.